FANFARE Multi-Detector

Very Early Warning Aspirating Smoke Detector

ULTIMATE PERFORMANCE! THE REAL MULTI ZONES.

FANFARE-2000 THE REAL FOUR ZONES

- FOUR High Sensitivity Smoke Detectors

- FOUR Aspirators

- FOUR Flow Sensors

- FOUR Bargraph & Indicators

- FOUR Sets of Additional Zone Relays

FANFARE-4000 THE REAL EIGHT ZONES

- EIGHT High Sensitivity Smoke Detectors

- EIGHT Aspirators

- EIGHT Flow Sensors

- EIGHT Bargraph & Indicators

- EIGHT Sets of Additional Zone Relays

THE ULTIMATE SPECIFICATIONS AMONG ALL

NOTE: FANFARE-2000:100Hole,FANFARE-4000:200Hole

ZONE DISPLAY

- Alert/Action/Fire 1/Fire 2/Fault Indicators for Each Zone

- 20 Segments Smoke Bargraph for Each Zone

LCD PROGRAMMER & DISPLAY

- Smoke, Flow, Address, Event/Error Code

- Alarm and Fault Indicators

- Reset/Isolate/Silence/Test Buttons

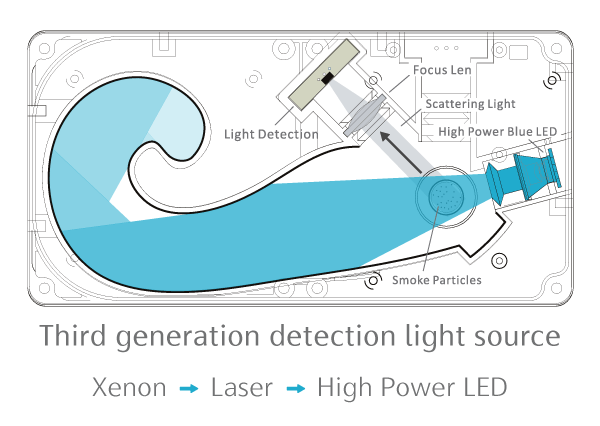

BLUE LIGHT DETECTION

►Wide Angle Nephelometer Mass Detection

| Air sampling pipe length | ||||

| FANFARE-2000 | FANFARE-4000 | |||

| Maximum Detection Area - Class A |

4x500m 2 | 8x500m 2 | ||

| Maximum Detection Area - Class B |

4x1000m 2 | 8x1000m 2 | ||

| Maximum Detection Area - Class C |

4x2000m 2 | 4x2000m 2 | ||

| Max. no. of Sampling Holes - Class A |

4x40 | 8x40 | ||

| Max. no. of Sampling Holes - Class B |

4x60 | 8x60 | ||

| Max. no. of Sampling Holes - Class C |

4x100 | 8x100 | ||

| - Single Pipe | 4x100m | 8x100m | ||

| -Two Brached Pipe | 4x2x100m | 8x2x100m | ||

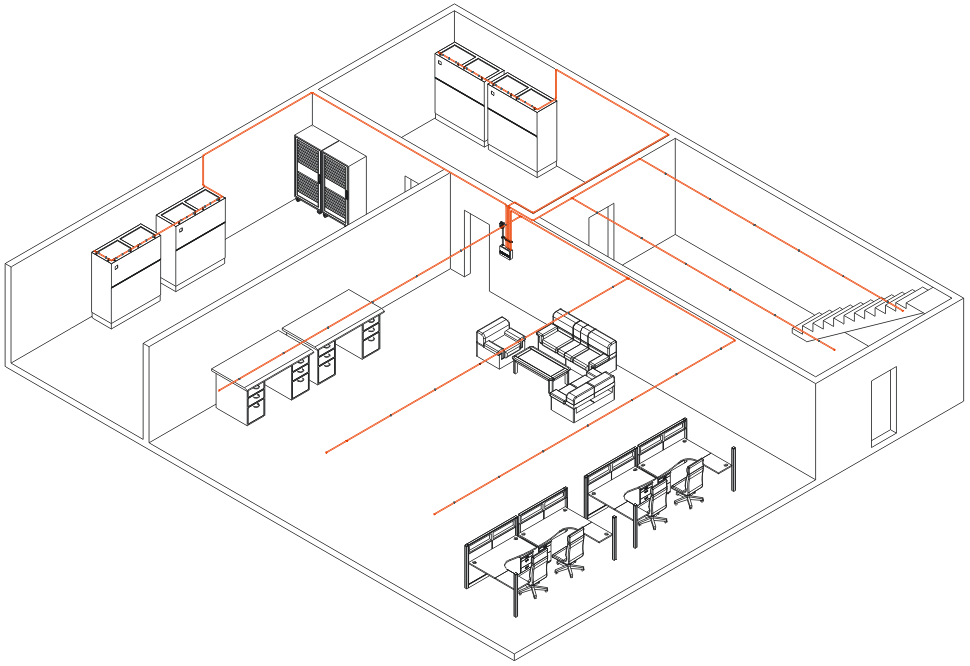

Multi-zone aspirating smoke detectors currently available on the market are mostly valve scanning type. Such products have only one smoke detector inside. The pipe in alarm is judged by switching on and off the mechanical valves located at the pipe inlet in sequence to find out the pipe having the most smoke. The kind of method to identify the alarm pipe (zone) is usually called “scan” process. Although this approach can work, but the scan process is time consuming. There is a lag to identify the alarm zone because it would take probably 40 to 60 seconds, or even more time to complete the scan process. More importantly, in an very early warning fire detection (VEWFD) application, there are high chances that the scan process would fail or misjudge the alarm pipe becaue the smoke increase is small when the fire is in incipient stage. It’s difficult for the device to distinguish the smoke change from the variation of smoke background level on different pipes protecting different areas.

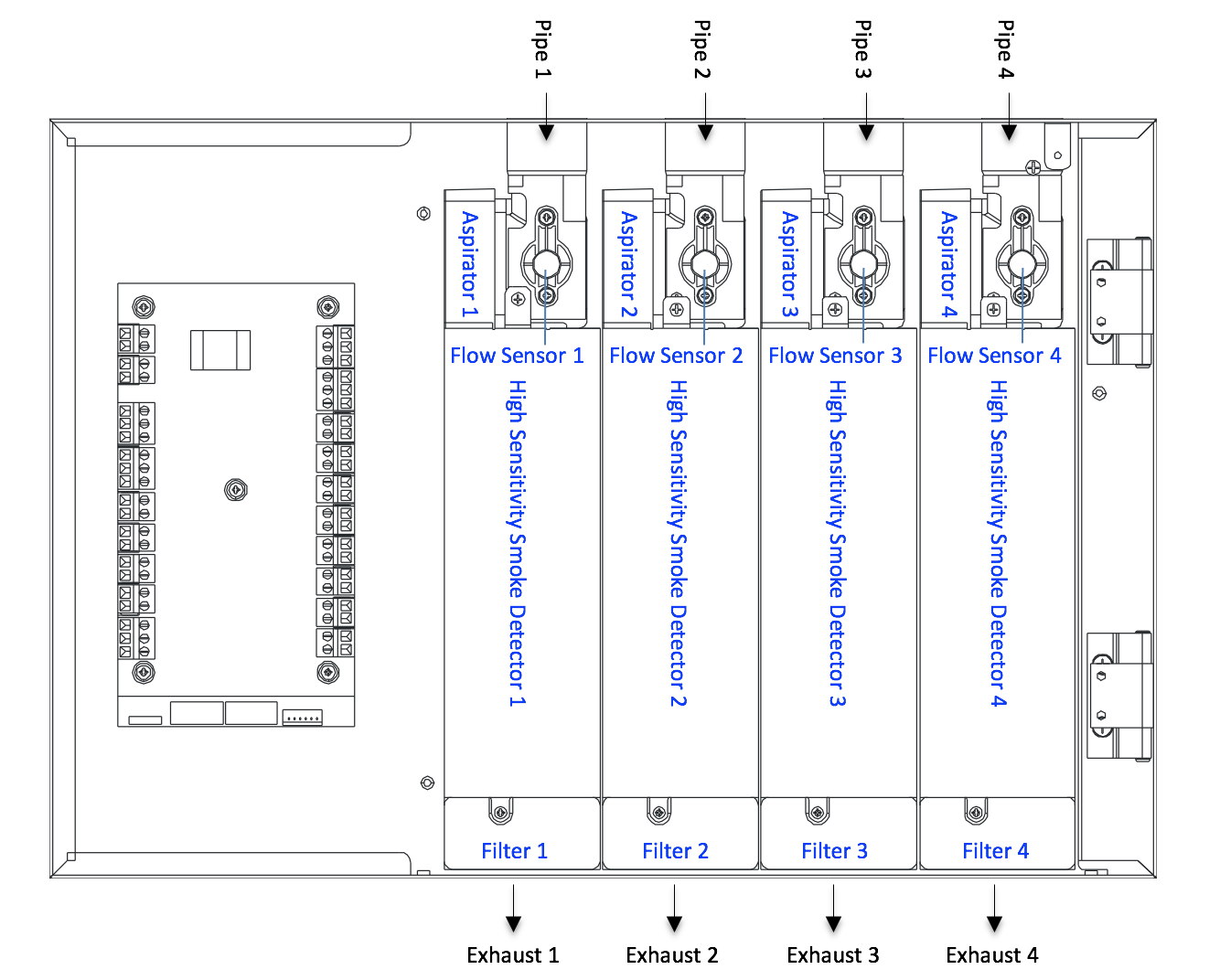

FANFARE-2000 is a real four zones aspirating smoke detector. It has four high sensitivity smoke detectors, four aspirators, four flow sensors, four filters. Each pipe is an individual detection zone. The advantages of FANFARE product are obvious. Each pipe’s smoke level and alarms are detected, displayed, and output at real time. In a glance on the FANFARE display you know which pipe (zone) is in a fire risk. No time lag at all.

However, the most important advantage among all is that FANFARE is more sensitivity and/or more immune to false alarm compared to four pipes one detector product. This is because the area (or the number of sampling points) covered by each detector of FANFARE is much less than traditional four pipes one detector product. This makes the sampling point sensitivity of FANFARE four times more sensitive compared to four pipes one detector product if their detector alarm threshold settings are the same. On the other hand, FANFARE is very much immune to false alarm compared to four pipes one detector product when their sampling point sensitivity is the same. To have equal sampling point sensitivity, the detector alarm threshold setting of four pipes one detector product should be 4 times more sensitive to FANFARE. The more sensitive the detector alarm threshold is, the more the probability to false alarm.

Illustration of FANFARE-2000 internal structure

Illustration of FANFARE-2000 internal structure

ASD Specifications |

|||||

| Items | QUARTAS-500s | QUARTAS-2000s | FANFARE-2000 | FANFARE-4000 | |

| Detection Light Source | High Power Blue LED | ||||

| Detection Principle | Forward Light Scattering | ||||

| Detection Sensitivity Range | 0.001~25 % obs/m | ||||

| Alarm Sensitivity Range | 0.005~20 % obs/m | ||||

| Alarm Level | 4 Stages (Alert, Action, Fire-1, Fire-2) | ||||

| Alarm and Fault Time Delay | 0~60 (Sec.) | ||||

| Sensitivity Switch | 2 (0.1~10) | ||||

| Flow Learning | 6 Flow Sensitivity Learning Mode | ||||

| Environment Smoke Learning | 15 / 60 / 120 / 240 / 480 minutes (Non-Stop) | ||||

| Fan Speed | 10 Steps Adjustable | ||||

| High Sensitivity Smoke Chamber | 1 | 1 | 4 | 8 | |

| High Efficiency Aspirator | 1 | 4 | 4 | 8 | |

| Flow Sensor | 1 | 4 | 4 | 8 | |

| Air Sample Inlet Port | 1 | 4 | 4 | 8 | |

| Air Sample Exhaust Port | 1 | 1 | 4 | 8 | |

| Two Stages Filter | 1 | 1 | 4 | 8 | |

| Local Display / Programmer | Numerical Value Display | Smoke Level / Flow Level / Address / Event Code and Aux. Sensor Level (if fitted) | |||

| Bargraph | 20 seg. Bargraph x 1 | 20 seg. Bargraph x 4 | 20 seg. Bargraph x 8 | ||

| Indicator LED | 10 (OK / Isolate / Alert / Action / Fire 1 / Fire 2 / Det'n / Flow / System /Aux.) | 6 (OK / Ioslate / Det'n / Flow / System / Aux.) + 6x4 (Fault/Alert/Action/Fire 1/Fire 2) | 6 (OK / Ioslate / Det'n / Flow / System / Aux.) + 6x8 (Fault/Alert/Action/Fire 1/Fire 2) | ||

| Control Buttons | 6 (Reset / Silence / Isolate / Test / Left / Right) |

8 (Reset / Silence / Isolate / Test / Left / Right / Up / Down) |

|||

| Beeper | Yes | ||||

| Programmer | LED Type | LCD Type | |||

| Remote Display / Programmer | Numerical Value Display | NA | |||

| Bargraph | |||||

| Indicater LED | |||||

| Control Buttons | |||||

| Beeper | |||||

| Programmer | |||||

| RS485 Network | Yes | ||||

| RS485 Repeater | Yes (Extend 1,200m) | ||||

| General Purpose Input (GPI) | 4 (Configurable) | 8 (Configurable) | |||

| Relay Output | 7 (Configurable) | ||||

| Zone Relay | NA | 16 relays (optional) | 16 relays | 32 relays | |

| Auxilliary Sensors | Optional (Temp./Humidity and Gas Sensors) | ||||

| Event and Data Logs | 180,000 (items) | ||||

| Sampling Pipe Length | Total Pipe Length | 240m | 640m | 640m | 1280m |

| Single Pipe Length | Single Pipe 100m, Branched Pipe 160m | ||||

| No. of Sampling Holes | Class A / VEWFD | 30 Holes | 40 Holes | 40x4=160 Holes | 40x8=320 Holes |

| Class B / EWFD | 60 Holes | 60 Holes | 60x4=240 Holes | 60x8=480 Holes | |

| Class C / SFD | 60 Holes | 100 Holes | 400 Holes | 800 Holes | |

| Maximum Coverage | 500m²;Max 1,000m² | 2,000m² | 2,000m² | 4,000 m² | |

| Sampling Pipe Specification | OD: Φ 25mm/ID: Φ21mm | ||||

| Capiliary Tube Specification | OD:Φ8 /ID: Φ5 | ||||

| Operating Voltage | 24Vdc ±6 | ||||

| Operating Current | 350mA | 730mA | 1.13A | 2A | |

| Ambient Temperature | 0~50°C | ||||

| Max. Temperature under Sun | 70°C | ||||

| Sampling Air Temperature | -30~60 ° C | ||||

| Operation Humidity | 0~95%RH, Non Condensing | ||||

| Dimensions (W x H x D) | 215 × 202 × 85mm | 415 × 259 × 108mm | 426 × 291 × 130mm | 670 × 291 × 130mm | |

| Weight | 1.5kg | 5.2kg | 7.5kg | 12.1kg | |